A MAC History Lesson

By William D. Ehringer

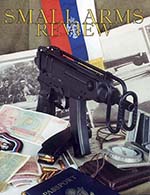

A Comparison Of The Military Armament Corporation Model 10/9 mm (MAC-10/9) And The Sylvia And Wayne Daniel M11 (SWD M11/9) and Other MAC-Type Weapons

When Gordon B. Ingram first designed his Model 10 (M10 in 9 mm and .45 ACP) in Los Angeles, California (those weapons are marked “Gordon Ingram”), little did he know that this design would be one that would captivate a number of different types of machine gun enthusiasts. His M10, in the early 1970s, embodied the spirit of making things smaller, more compact, and less expensive. He also believed in the philosophy that the fewer the working parts, the less that things can break. His theories are now axioms, as the MAC has become almost notoriously known as the most reliable sub-machine gun ever built. Since I currently own examples of several MAC-type weapons, I took the time to write down the differences and do a little research on the history and development of the guns and the companies that built them. In no way am I claiming that this is an all-inclusive list of all the information on MACs. That topic would be better dealt with in a comprehensive book on this subject. Rather, this short narrative is intended to give the MAC enthusiast a feel for the differences and similarities between the two most popular transferable SMGs ever built as well as providing a little history on the MAC-type weapons.

(Interestingly, as the author was preparing this manuscript I had the pleasure of speaking with a gentleman by the name of Don Thomas. Mr. Thomas was the Ingram/Sionics/Military Armament historian and is in the process of writing a comprehensive book on the MACs, Ingrams and Gordon Ingram’s biography. Mr. Thomas is always in search of information on the MACs and accessories and would appreciate hearing from any of the readers of this article (Mr. Thomas’ name and address can be found at the end of this article). If you have ever wondered where the name “Military Armament” came from, well you will be surprised to discover that this was Mr. Thomas’ FFL/SOT company trade name. When SIONICS (Studies In Operation Negation of Counter Insurgency) was looking for a new name to match its change in products...suppressors to Ingram machine guns...they discovered Mr. Thomas’ company and “purchased” his trade name.)

While many have belittled the MAC as a “cheaply made and affordable” machine gun, it does have a number of attributes which make it worthy of consideration as either a “first time” buy or as an addition to an extensive collection. In this author’s opinion, the MAC-type weapons fill an important niche that no other submachine gun has provided. Clearly what separates the MAC from other submachine guns is its diminutive size, overall performance and reliability, availability of spare parts, numbers of transferable units, cost, and add-on accessories. When you compare the MAC to other submachine guns (Figure 1 and Table 1) it becomes increasingly apparent that this gun fills an important niche, especially in terms of size and capacity, in the submachine gun market.

From the time the first MAC weapon was produced until today, a number of different questions have evolved over models and design features (Table 2). The most common question (which is really a mistake) is what is the difference between a MAC-10 and a MAC-11 in 9 mm. For those of you who are into MACs, you know that the MAC-11 is the .380 version of the gun. This question is usually meant to be “What is the difference between a MAC-10/9 and a SWD M11/9?” There are seven distinguishing differences between the SWD M11/9 and the MAC-10/9, and they are as indicated in Table 1.

1. The SWD M11/9 is made of a thinner gauge of sheet metal compared to the MAC-10/9 (Figure 2). The thickness of the lower receiver of the SWD M11/9 is 0.068” (15 gauge), while the MAC-10/9 is 0.095” (13 gauge). The big reason for the difference was not so much the cost but was the weight (Table 2). While the MAC-10 is a light weapon, the SWD M11/9 is even lighter. My feeling is that this makes the SWD M11/9 easier to conceal, and is especially true for its .380 cousin. In fact, discretionary briefcases were made for these two guns, which allows the operator to fire the weapon from inside of the briefcase without removing the weapon. The thinner gauge of metal on the SWD M11/9 has not proven itself a disadvantage as far as durability goes, at least in my case, as I have put thousands of rounds in my SWD M11/9 with no appreciable signs of wear or stress. In addition, early Powder Springs manufactured MACs lack the reinforcing tabs on the front take down hole. In contrast, the SWD M11 has the reinforcing tabs, which is a piece of sheet metal TIG welded to the inside of the frame. The Powder Springs MACs are notorious for wallowing-out the front takedown pin hole. Because of the reinforcing tabs, the SWD and some RPB guns have a smaller front barrel block.

2. The SWD M11/9 uses a different cocking knob (flat round knob) than the MAC-10/9 (smaller around, but taller)(Figure 3). The cocking knob on the MAC-10/9 also acts as a safety, because turning it 90 degrees will lock the bolt in the forward position. The MAC-10/9 knob is also slotted on the top, so that you can actually aim the gun using the peep sight. In contrast, the SWD M11/9 cocking knob lacks the detent and locking feature. Thus, owners of SWD M11/9s should never insert a loaded magazine into the gun until the weapon is ready to be fired. Also, sighting using the SWD M11/9 cocking knob is made near impossible because the cocking knob interferes with sighting. While older designed SWD cocking knobs were slotted, the newer ones are not (see Figure 3). Furthermore, the original SWD M11/9 cocking knob is not ergonomically designed as only one finger can fit on the knob for cocking the guns near 20-25 lb bolt pull. Recently Tactical Innovations, Inc introduced a newly manufactured cocking knob for the SWD M11 that is similar in design to the older style but has a number of improvements.

3. The SWD M11/9 uses a Zytel or steel magazine whereas the MAC uses steel mags only (Figure 4). The Zytel mags have had mixed reviews as far as reliability goes. The major problem with the Zytel mags was that the feed lips would bend or break, causing reliability problems. The other major problem with the Zytel mags was that the seam along the back of the mag would split after being filled to capacity. Fortunately, there are a number of solutions to this problem. Tactical Innovations sells a STEn magazine well conversion kit that is easily installed on the SWD M11/9 allowing the use of cheap, reliable STEn magazines. In addition, one can also use modified Madsen mags (C&S Metall Werkes) in the SWD M11/9. The MAC-10/9 uses a modified Walther MPL 36 round mag, (which are becoming scarce...read expensive), but this mag was less susceptible to failures than the Zytel mag. The MAC-10/45 uses modified M3 Grease gun magazines. These mags are modified to fit the MAC-10/45 by shaving 1/16” of steel off of the rear of the magazine (for the mag catch) and 1/16” off the two locking tangs on the side of the magazine. The SWD M11A1 in .380 and the MAC-11 in .380 are the guns that cause the most confusion in regards to magazines. The SWD M11A1, which is a shortened M11/9, uses the same magazines as the M11/9 except the feed lips have been heated and bent to accommodate the diminutive .380round and these magazines are heat stamped “380”. The MAC-11 uses a smaller steel magazine which are rare and often expensive. The SWD M10/9 uses the same magazines as the SWD M11/9, but can also use modified Madsen mags or can undergo and STEn mag well conversion.

4. The SWD M11/9 bolt is smaller, and instead of having a fixed firing pin milled into the bolt face (ala the MAC-10/9), it has a firing pin that is pinned in place (Figure 5). Numerous other design differences exist between the SWD M11/9 bolt and the MAC-10/9 bolt and include: Dimensional differences, presence of a front detent for the MAC-10/9 cocking knob, slight weight difference, and overall length difference of the entire bolt, recoil rod and ejector rod assembly. The SWD M11/9 bolt is the same exact bolt used in the closed bolt semi-auto guns, with the exception that the SMG bolt’s firing pin is not slotted, the bolt lacks the firing pin spring, and the front of the bolt is notched to engage the sear. Since the firing pin on the SWD M11/9 is nothing more than a piece of sheet metal, owners of these guns should buy an extra firing pin as a spare. One final note, the SWD M11A1 380 SMG bolt is nothing more than a SWD M11/9 bolt cut-down to allow the smaller 380 cartridge to function.

5. The upper of the SWD M11/9 is also smaller in diameter (1” square I.D.) compared to the much larger MAC-10/9 which is about 1.5” square (Figure 6). While the SWD is smaller and more flat, it is also slightly longer (about 1”) than the MAC-10. My guess was that this dimensional difference was done to compensate for the lack of weight in the SWD 9 mm bolt, by giving it a slightly longer cycling distance. The factory cyclic rate of both guns is still very high, in the 1100-1200 rpm range, which means that a 30 rnd mag can be emptied in about 1.5 seconds by either gun. My experience is that the MAC is a tad bit slower than the SWD, but for all intents and purposes, they are both fast cyclic rate guns.

6. SWD M11/9s are more prevalent than the MACs. Wayne Daniels, the founder of SWD made about 17,000 of the M11/9 SMGs, 3,800 M11A1 SMGs in .380, and 500,000 semi-auto M11/9’s. In contrast, the number of original Powder Springs MAC-10/9s is much smaller, and even more rare is the MAC-11/.380. While other manufacturers made copies of the MAC-10 (see table 1), its collective numbers still do not rival the SWD M11/9. Recently, JLM and Sons purchased nearly the entire remaining inventory of SWD M11/9s and SWD M11A1s from FMJ/Mountain Accessory Corporation.

7. SWD M11/9 is about half the cost of a MAC-10. Believe it or not, the MAC is becoming a collector’s item. I know, when you bought your MAC-10 in 1975 you paid $125, but guess what, the gun is now worth in excess of $1200. And because the supply is fixed and the demand continues to increase, the value of the MACs only continues to rise. To a lesser extent, the same goes for the SWD M11/9. In fact, since March of 1998 the price of the SWD M11/9 has risen from $495 NIB to $750 NIB (as of the writing of this article). Nonetheless, the SWD M11/9 remains one of the best buys in the machine gun market.

The above seven differences are certainly not inclusive of all MAC-10/9s as a number of other companies also made the MAC and other design differences and similarities are possible. I have tabulated some of the differences below and in Table 1 on the manufacturers and lineage of the MAC-10.

Military Armament Corporation (MAC), Powder Springs and Marietta, Georgia. MAC was based in Powder Springs Georgia from the early 1960s until they moved to Marietta, Georgia in the late 1960s, and later went bankrupt in 1975, was the first company to commercially produce the MAC Model 10 (MAC-10). This is the company started by Mitch L.WerBell III and his family and which utilized the talents of Gordon Ingram and Max Atchisson and John Foote. Ingram designed and built the first MAC (now you know where the name “Ingram submachine gun” came from, and how it can often be confused with MAC). MAC marketed a number of different weapons, but the MAC-10 (chambered in 9 mm and later in.45 ACP) and the high cyclic rate (approx. 1600 rpm) MAC-11 (chambered in .380) were its mainstays. The bankruptcy of MAC was the result of a mismanaged “top heavy” (at one time they had over 75 executives and employees) organization. Many of the tooling and assets of MAC were sold to another Georgia-based company called RPB in 1977.

(Note from Don Thomas, SAR Staff Archivist) During the late 1960’s, a bitter corporate war took place at Military Armament Corporation after the company had moved to Marietta, GA from Powder Springs, GA. When the dust had settled, Gordon Ingram and the WerBell family had been forced out of the company. Still in a vengeful mood, the company immediately changed the name from the Ingram Submachine Gun to the MAC Submachine Gun. From that time until the eventual bankruptcy of Military Armament Corp., the gun, manuals, sales literature and all other documentation was marked “MAC Submachine Gun”.

RPB, Atlanta, Georgia. This company whose acronym was rumored to stand for Rape, Plunder, and Burn, actually is the initials of its company founders: Ray Roby, Charlie Pitts, and Richard Brueggeman. Roby, Pitts, and Brueggeman were former MAC employees who bought the tooling, frames and parts at the MAC auction. They made the MAC in the same calibers as did the Powder Springs/Marietta Plants, but in some collectors eyes the manufacturing was not on par with the original MAC. Nearly all of the machine guns that came from RPB were either frame flats, frames or completed guns which were bought from MAC in the auction. Because the machine gun market at that time was not as popular as it is today, RPB came up with a new marketing strategy, which was to offer the MAC-10 as a Title I weapon (a semi-automatic) creating an open bolt semi-automatic firearm. BATF stepped in mid-1982 and halted the manufacture of open bolt semi’s because they were easily convertible to full-auto. A few years after Roby, Pitts, and Brueggeman started RPB, they were bought out by Wayne Daniel. Wayne Daniel continued to use the RPB name for several years until changing the name to SWD.

SWD Incorporated, Atlanta, Georgia. In 1983, Wayne Daniel modified the existing MAC design and created the SWD (Sylvia and Wayne Daniel) M11/9. The gun was MASS-PRODUCED, and that is the reason that so many are still offered for sale NIB. Daniel differed from his predecessors in that he was a marketing genius, kept his company small and manageable, and worked along side his employees. This is one of the reasons Daniel was so successful when compared to MAC or RPB. Daniel also understood the gun market, and marketed his gun as a Title I and Title II weapon. When the MG ban went through in 1986, SWD continued marketing the closed bolt design Cobray M11/9. This semi-auto uses the exact same machine gun receiver as did the full-auto SWD M11/9, with only a few exceptions (selector switch not drilled, sear pin, and re-enforcing plates absent). After the Assault Weapons Ban in 1994, the Cobray M11/9 could no longer be made, so Cobray re-marketed the gun with a non-threaded barrel and no mag release as the PM-11/9.

MAC, Stephensville, Texas. James Leatherwood took the MAC design from the Powder Springs plant and redesigned the gun to be “better”. In short, Leatherwood redesigned the trigger mechanism, the safety, and the stock. Some of these improvements were viewed as “improvements” others were viewed as “disappointments”. The guns built by Leatherwood were also tack welded rather than TIG welded. This turned out to be the biggest disappointment as the “Texas MAC” has a reputation of shaking their tack welds loose and in some cases injuring the shooter. Many of the Texas MAC frames (I have heard in excess of 1000) were purchased by Wayne Daniel when Leatherwood’s operation folded. These “Texas MACs” frames were built-up using RPB and Cobray parts and most importantly, they were TIG welded. The SWD Texas MACs use a SWD magazine housing, SWD grip, SWD 9mm barrel, and most importantly the SWD Zytel mags.

Jersey Arms, Indian Mills, New Jersey. This company built M10/9s and M10/45s before folding in the early 1980s. These guns were built using essentially the same designs and principals as the PS and RPB guns and were made by Hatton Industries in Indian Mills, New Jersey and many were marked, “Commando Avenger.” The big difference between the Jersey Arms guns and the rest of the MACs was that the Jersey MAC was full-auto only, and lacked a selector switch. Additionally, the Jersey gun will not accept a standard wire M10-type stock. The welding of these guns was adequate but let’s say lacked finesse. Many of the Jersey Arms guns were also blued, rather than parkerized like the other MAC-type weapons.

Section Five Firearms Ltd. The MAC Model 10 was also produced by an overseas firm located in the United Kingdom called Section Five Limited. The Sections Five Limited guns were made in 9mm and are kind of unusual in that it uses an UZI grip frame and magazines. “Section Five” refers to the section in British law corresponding to our National Firearms Act branch of the Bureau of Alcohol, Tobacco, and Firearms. I have no knowledge of any “official” users of these, but they no doubt were exported around Europe, since none could be legally held by civilians.

Suppressors... The original suppressors for the MACs were made by SIONICS. The MAC-type weapons were originally designed to be fired using a sound suppression device. Anyone who has fired a MAC-10/45 and emptied a 30 round mag knows exactly what I mean! Below are a few of the design characteristics of the original MAC suppressors. It is important to note that while the MAC suppressors were, at the time, state of the art in sound suppression, there are many new and innovative MAC suppressors that are now far superior in design.

The suppressors for the MAC-type weapons are of the thread-type and this is another difference between many MAC-type weapons. The thread pitch for SWD M11/9, SWD M10/9 and the MAC-10/9 is 3/4” x 10 TPI, the SWD M11A1 and MAC/RPB M11/380 has a 5/8” x 11 TPI thread pattern, and the MAC and RPB MAC-10/45 is threaded 7/8” x 10 TPI. Two types of MAC suppressors were factory made for the MAC-type weapons: a single-stage suppressor that used polyurethane wipes and a two-stage suppressor that was wipeless in design (Figure 7). The two-stage suppressor was the original can made for the MAC. The single stage suppressor came along afterwards and was the one hated by its owners, and later by the ATF. The big reason for this hatred was that for the suppressor to achieve decent sound suppression, the internal wipes had to be replaced after only a couple hundred rounds. This is when Gun Show vendors started selling replacement polyurethane “wipe kits.” Problem was, that the same vendor would also sell the tubes the wipes fit in, and those individuals who made a suppressor in violation of the NFA ruined it for us all. This is when ATF ruled that any suppressor part was indeed a suppressor and had to be either registered or in the possession of a Class 2 manufacturer. Well as you can imagine, this shut-down the “spare suppressor parts business” and owners of these cans had a “limited life suppressor.”

On the other hand, the two-stage suppressor can be easily disassembled and cleaned. It is easily distinguishable from its single stage cousin, because it has a larger tube screwed into a smaller tube, whereas the single stage is just a straight tube. Inside of the first stage of the suppressor (which cannot be readily disassembled) are shoestring eyelet’s. The second stage contains an inverted baffle cone, then two spiral-type baffles held in place by an encapsulator. Threaded into the end of the suppressor is the only “disposable part” which is a rubber or wax-type grommet end cap. Going price for a single-stage suppressor is about $125-200, while the two-stage suppressor is in the $200-300 range (depending upon manufacturer and condition). RPB and MAC made two-stage cans, while SWD made the single stage cans.

.22 LR Conversion Kits for the MAC-Type Weapons...If you own a MAC-type weapon, you will soon find out that these guns love to eat ammo, and at $3-4/magazine in ammo being shot from the weapon in less than 2 seconds, it is all important to find an economical alternative. The .22 conversion kits for these weapons are the answer. While working at Military Armament Corp., Max Atchisson designed a .22 conversion unit for the AR15/M16 rifle. Sentinel Arms is believed to have manufactured the first .22 conversion kit for the Ingram/MAC Submachine Guns.

The next most frequently encountered MAC-type conversion kit was the one made by Bill Fleming for the SWD M11/9. This kit was radically different than the original Atchisson kit because the upper receiver was made slightly larger so that the upper and bolt could accommodate a 10/22 magazine that was mounted on the side of the upper. The kit consisted of an upper with magazine well, a 22 barrel threaded 1/2 x 28 TPI (to accommodate suppressors, flash hider, etc), a bolt and a recoil rod and spring. These kits had numerous reliability issues which centered around several factors: The ejection port was not large enough in size, the extractor was poorly designed, and the inside of the upper and the bolt were rough and added friction to the movement of the bolt. Interestingly, this kit was sold in both left and right hand ejection models for the “double your pleasure crowd”. These kits sold for $199.95 new in 1993.

Recently, Craig Wheatley of Tactical Innovations introduced two different types of 22 conversion kits for the SWD M11/9. The first, which was a limited run (approximately 30 units) was identical in design to Fleming’s 22 conversion kit, except that Craig altered his design to correct for the design flaws that plagued the Fleming kits. These kits sold for $250 and often are currently sold for in excess of $400. Last year, Craig introduced a newly designed 22 conversion kit (cost $379) which is completely different from the Fleming/Tactical Innovation kits just described. This kit utilizes a standard M11 upper that has been modified to accept a newly designed bolt. The charging handle for this kit is on the right side, while the magazine (a modified Uzi 22 magazine) fits in the original magazine well. Craig also modified the bolt so as to slow the cyclic rate of the conversion kit down so that it will give users additional time to empty its 15 round mag. A 30 round mag for this conversion should be available by the Fall of 1999.

Summary...The MAC-type weapons are excellent examples of submachine guns that have found favor with both experienced collectors and novices alike. While the choice of either the SWD M11 or the MAC M10 is an excellent choice as a SMG, especially as a first time NFA weapons purchase, the biggest complaint about either gun is that they have very high cyclic rates. This is great when you first get the gun, but after the “fun” of dumping $3-4 down range in 1.5 seconds ends, most owners start seeking more “accurate means.” Problem is, accurate usually spells expensive and thus the MAC-10 and SWD M11/9 owners were left with a bullet hose. However, others and I have developed a means to convert a standard SWD M11/9 SMG into a VERY competitive SMG. In fact, the SlowFire M11/9 has beaten out MP-5s, M16/9s, and other rare and expensive SMGs in competition. I and every other MAC owner agree wholeheartedly and we can only thank the genius of Gordon Ingram for his beautiful, well designed submachine gun.

The author would like to acknowledge the grateful assistance of the following individuals and companies who made this article possible: Tom Bowers, Don Thomas, Scott Baber, and Martha Brown, Doug Kiesler, and Terry Rush at Kiesler’s Police Supply.

Et Cetera, L.L.C.

PO Box 929

Copperhill, TN 37317

1-800-642-1600 (orders only)

423-496-9050 (questions)

423-496-2111 (FAX)

RPB Industries

PO Box 367

Avondale Est. GA 30002

1-800-858-0809 (order only)

404-297-0907 (questions)

404-297-0917 (FAX)

Tactical Innovations, Inc.

PO Box 3

Glen Burnie, MD 21060

410-760-3609

Mr. Don Thomas

MAC/Ingram Historian

2888 St. Andrews Way

Marietta, GA. 30062

770-973-8421

C&S Metall-Werkes, Ltd.

4025-O Old Hwy 94 S

St. Charles, MO 63304

(314) 928-1511

This article first appeared in Small Arms Review V3N2 (November 1999) |

| SUBSCRIBER COMMENT AREA |

Comments have not been generated for this article.